Rapid Prototypes&Prototyping

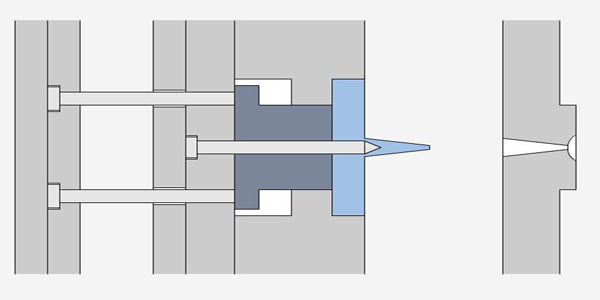

Prototype injection molding can improve you create the parts before you production. Prototype molded parts can be produced for your testing part geometry, functionality and low-volume production. These prototype molds are typically produced out of aluminum, as well as they can also be made of steel. we are able to offer quantity prototype injection molding services for you.

Rapid mold, you can also call it prototype tooling or bridge tooling, this is a fast and cost-efficient way to bring low-volume injection molding for a variety of types of plastic parts. this mold can use material aluminum or steel to build mold has been created with the rapid mold process. So rapid mold is used to create moldings for rapid prototyping needs in a shortened time frame or they can to bridge the gap before high-volume production.

Combine our experience, engineering capabilities and advanced technology to produce high-quality rapid mold solutions for prototypes and short production runs. Our team works directly with each customer to ensure that we create the perfect solution. Our experience speaks for itself. The team is well-equipped to handle your rapid tooling and mass production mold making requirements

Economy of Scale

Many cases shown the rapid tooling is the most cost-effective option for an order of 100–10,000 units: too many for 3D printing, CNC machining, or urethane casting, but not enough to justify mass production tooling

Top Quality

To prototype mold, we can produce high-quality moldings which are very close to mass production, or 100% matching the final production level

Material Options

There are many material for rapid tooling and it is a wide range of material options is, usually ,we use aluminum to be made the rapid tooling for samples but it is also depends on the customer for the quantity

Customizable Finishing

In rapid injection molding, we can tailor molds to produce different finishes including smooth, glossy, and textured. Further finishing procedures such as painting, chroming, and silk-screening can then be applied to the moldings

Benefits of Rapid Tooling

Rapid production tooling gives a number of advantages over other methods of prototype production:Fast processing: Prototype tooling provides quick results, so the transition between development and production is very short.

Customization: The rapid tooling process still allows for advanced customization of the mold.

Proof of concept/testing: Rapid prototyping facilitates practical real-world design testing and troubleshooting solutions. It also enables quick and precise production of new tooling that implements design changes and improvements.

Speed to market: Fast production and accurate tooling contribute to efficiency in production, ultimately providing a faster introduction to the market than other methods.

Competitive pricing: The affordability of the rapid tooling process translates into a positive impact on the bottom line for our customers.

Rapid Tooling FAQ

Why should I use rapid tooling?Rapid tooling is a fast and verify testing and part function ,it is a cost-efficient way to create a few prototypes in a selected material for function and aspect testing, as well as for low-volume manufacturing to test out the market.

How fast can I get the moldings?

This depends on the part of size and geometry. For a common open and shut mold with regular size part such as 200 x 200 x 40 mm, the manufacturing of tools and moldings can be done within 10 days.

What materials can I choose from with rapid tooling?

There is no limit to material choice. Any plastics available for mass production, including common silicone and rubber materials, can also be used with the rapid tooling process.

What is the quality level of rapid tooling?

Moldings from rapid tooling are end-use-parts quality. after improved tooling from testing and function ,it is very close to mass production parts.

How many moldings can I get from rapid tooling?

Normally, if it is aluminum it will be made for +/- 1,000 shots, if use steel P20 molds can last for +/- 10,000 shots.

TOPSMOLD

TOPSMOLD